Contact

Contact

How can we help?

How can we help? - 01Chat we us

We are here to serve you.

We will assist you in person and comfortably through the Internet from 9.30h to 14h and from 15h to 18h.

- 02Call us

Contact

Monday to Friday from 8.30 - 14h / 15h – 18h

- 03Do you prefer that we call you?

Leave us your phone number and we will contact you to help you with whatever you need.

Schedule of attention: 8.30 - 14h / 15h – 18h, monday to friday.

Jekko lithium batteries

We present the Jekko lithium batteries to the Movicarga awards.

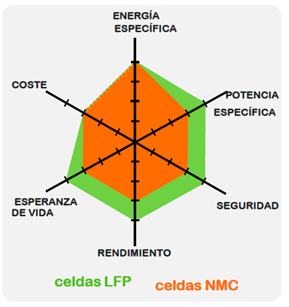

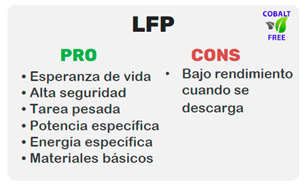

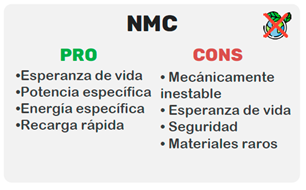

Battery types

This technology is everywhere today and has multiple possibilities in its chemical composition. For the sake of simplicity, the most used lithium batteries in the automotive industry are considered:

•LFP composed of LiFePO4: Lithium Iron Phosphate

•NMC composed of LiNiMnCr: Lithium Nickel Manganese Cobalt

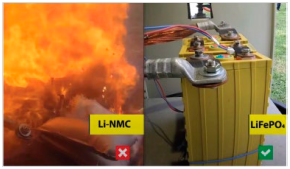

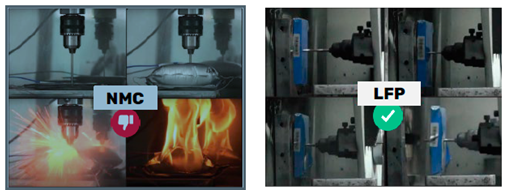

LFP vs NMC –Safety factors

To define the goodness of the battery type, in addition to capacity and durability, two other factors must be considered: thermal runaway and the nail penetration test.

THERMAL EXHAUSTS

Situation in which an increase in temperature creates an additional increase in temperature inside the battery. This causes an uncontrolled deviation from equilibrium conditions, causing fires and explosions. It can be caused by overcurrent and adverse weather conditions. Depending on the chemistry adopted, the thermal runaway phenomenon is different:

• NMC: The system generates approximately 200°C/min, making repair or replacement impractical;

• LFP system generates around 1.5°C/min, making repair work possible and safe;

TEST

This is the best test to define the behavior of the cell under critical shock, vibration or shock conditions. The difference in the behavior of the two types is the following:

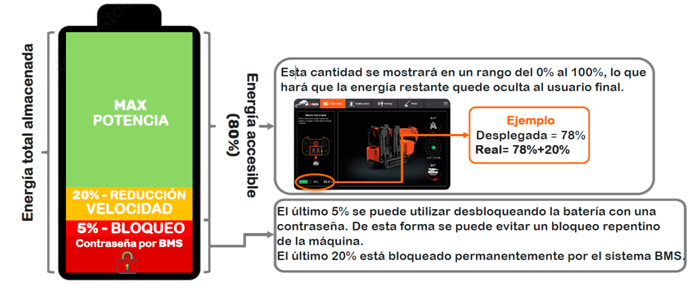

Enery management

The lithium battery is very powerful and long-lasting if used correctly. The worst condition for lithium cells is deep discharge. To facilitate management, an intelligent system prevents this from happening. In addition, the BMS (Battery Monitoring System) will maintain the last 20% reserve, significantly extending the useful life of the battery.

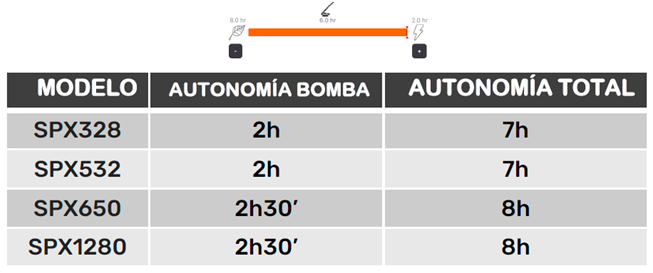

Nominal autonomy

Thanks to the Start&Stop system, the pump will only work if there are active functions, otherwise it will remain completely off, saving a lot of energy.

Duty cycle

An estimate made from long experience is 30%. This means that the pump will be running 2h30' during the 8h work day.

Power consumption

A constant average consumption of approximately 50% of the maximum power. It is also possible to considerably increase the autonomy (up to +100%), reducing the revolutions of the pump,

NOTE: the data is based on the calculation sources mentioned above and may vary depending on the use of the machine.

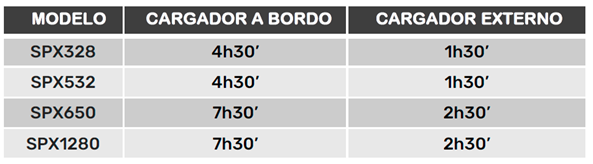

Charging time

Recharging can be done with two different chargers: onboard battery charger external battery charger The machine can operate in all its functions while recharging, benefiting work efficiency and the battery itself. Additionally, this will ensure 100% duty cycle. Considering starting recharging when 10% SoC (State of Charge) is reached:

To extend battery life it is recommended to reach 100% SoC weekly, to perfectly match the lithium cells. The load is managed intelligently, stopping the process automatically once the maximum load is reached.

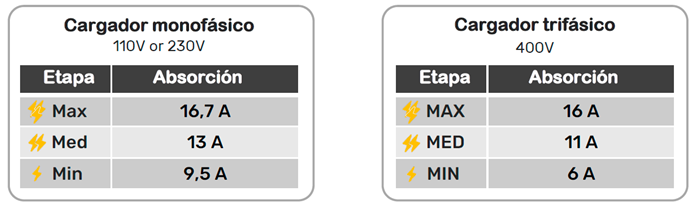

Current Settings

The integrated display offers the possibility of setting different absorption levels, making charging possible even in conditions of low line power supply. This will ensure continuous worry-free work for the SoC. Below, the configurable charging current:

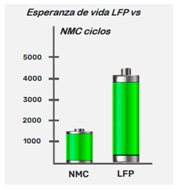

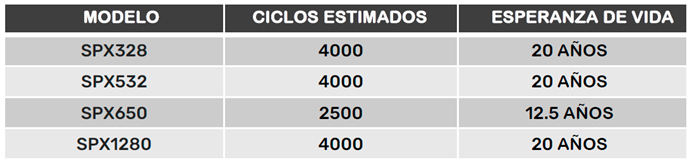

Life expectancy

The stored energy will remain unchanged depending on the charging cycles.

A cycle is counted when:

- Charger on

- Charger disconnected and battery in use.

- Charger connected again Depending on the machine model, the number of cycles is different.

Considering 200 business days a year, with daily recharge:

After the indicated cycles, the battery will begin to proportionally reduce the maximum stored current

Optional battery

Among the various options, in SPX532 and SPX650 there is also the possibility of having the machine with a larger lithium battery pack. This means that the machine will have a greater amount of energy and consequently a significantly greater autonomy.

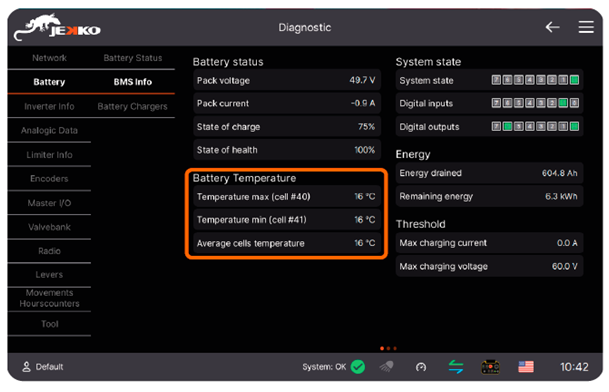

Low temperature

The minimum operating temperature is -10°C (14°F) and the minimum stock temperature is -20°C (-4°F). However, the charging current below 0°C will be reduced, requiring more time to recharge. Thanks to the integrated display it will always be possible to monitor the battery temperature and other information.

Maintenance

Unlike traditional batteries, the lithium battery does not require maintenance. Equalizing the battery as stated above will ensure optimal conditions. The Start&Stop system will greatly reduce the circulation of hydraulic oil, significantly reducing filter clogging. Making a rough comparative calculation, it turns out that a fully electric machine requires 65% less maintenance than a machine with a combustion engine. Additionally, this will completely eliminate traditional combustion engine maintenance that must be performed every 250 hours of operation.